Comments Off on Industry News: Thailand Livestock, Animal Health and Animal Nutrition- July 2024

Industry News: Thailand Livestock, Animal Health and Animal Nutrition- July 2024

Comments Off on Industry News: Vietnam Livestock, Animal Health & Animal Nutrition

Industry News: Vietnam Livestock, Animal Health & Animal Nutrition

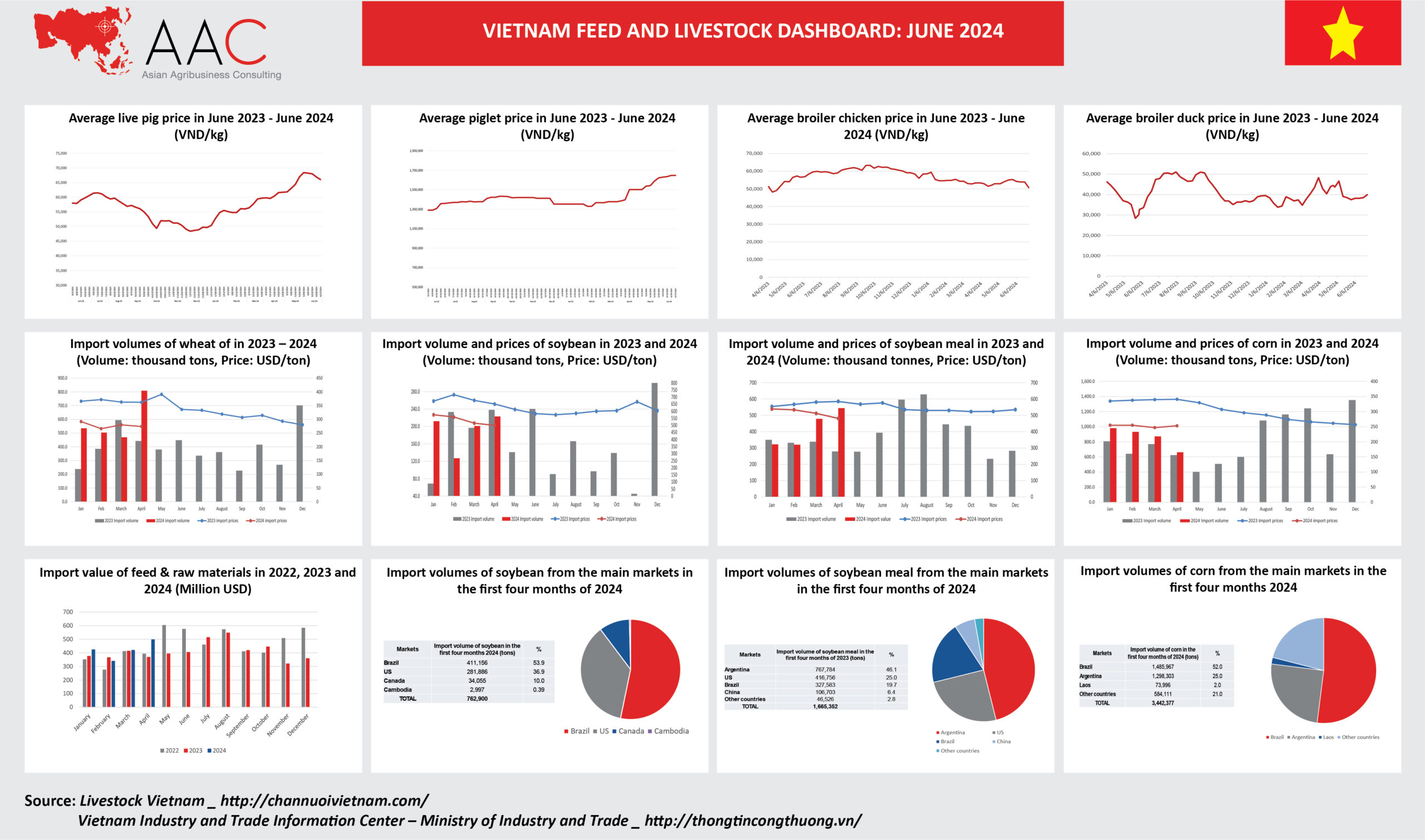

Comments Off on Vietnam Feed and Livestock Dashboard: June 2024

Vietnam Feed and Livestock Dashboard: June 2024

Comments Off on Industry News: Thailand Livestock, Animal Health & Animal Nutrition

Industry News: Thailand Livestock, Animal Health & Animal Nutrition

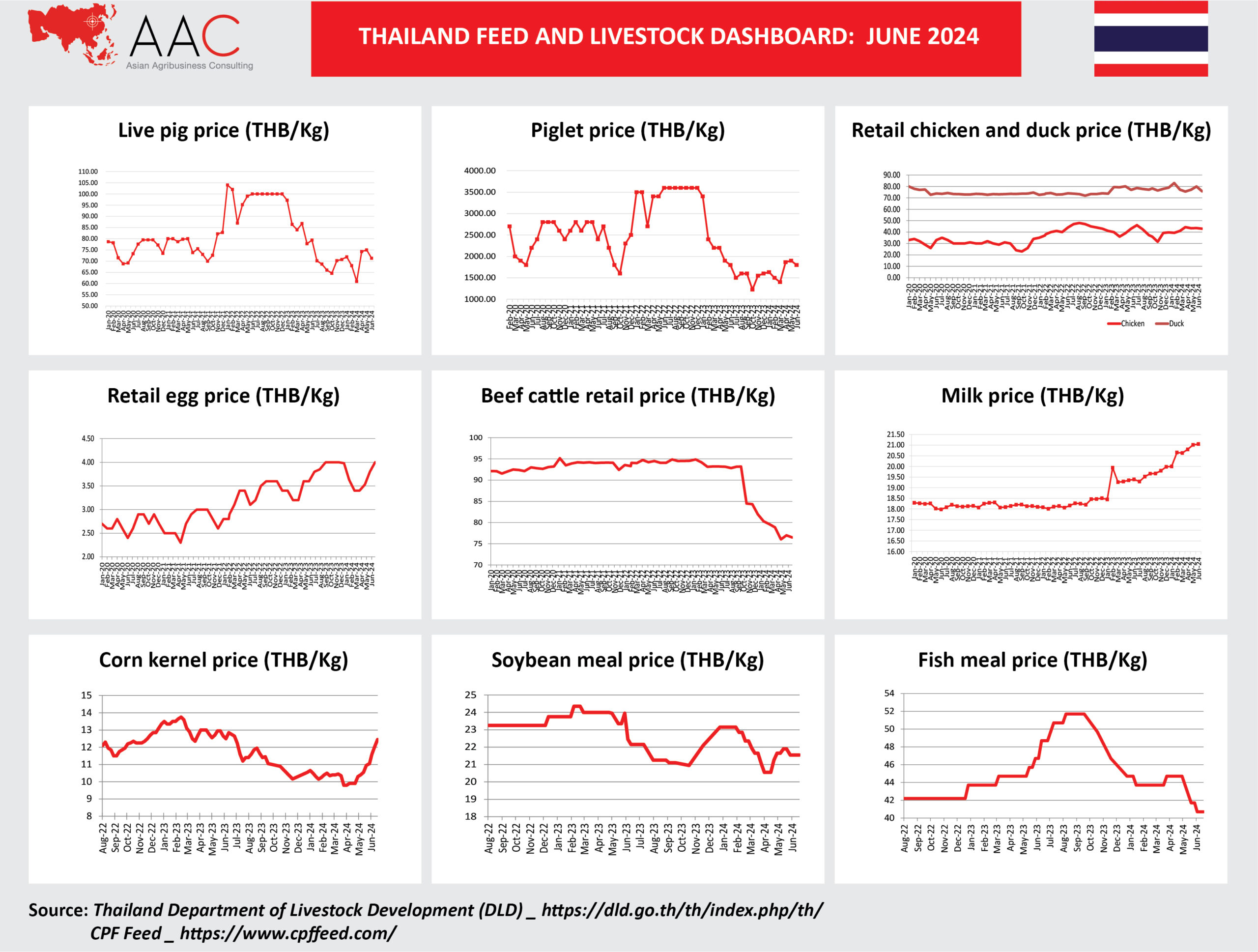

Comments Off on Thailand Feed and Livestock Dashboard: June 2024

Thailand Feed and Livestock Dashboard: June 2024

Comments Off on Industry News: China Livestock, Animal Health & Animal Nutrition

Industry News: China Livestock, Animal Health & Animal Nutrition

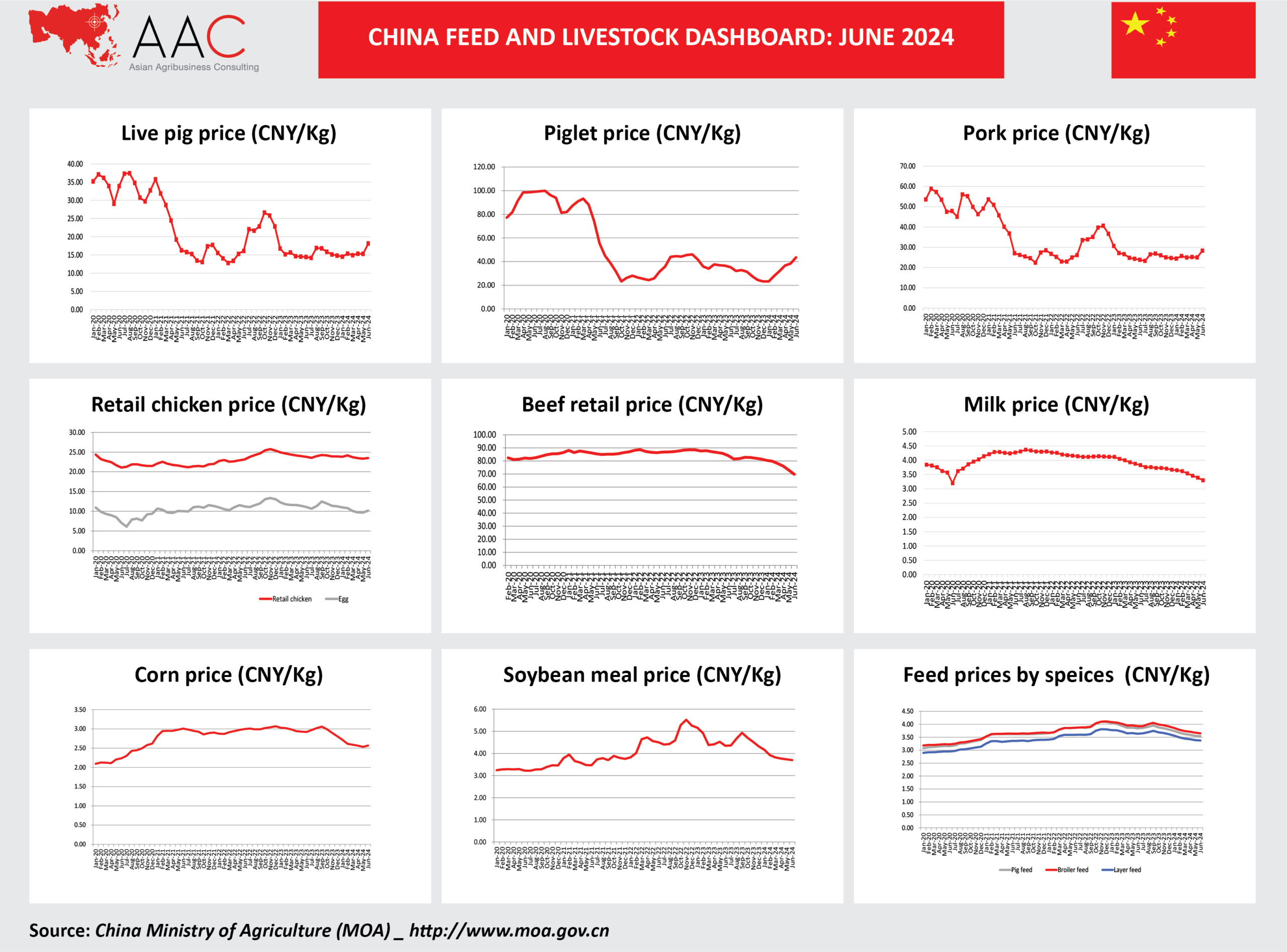

Comments Off on China Feed and Livestock Dashboard: June 2024

China Feed and Livestock Dashboard: June 2024

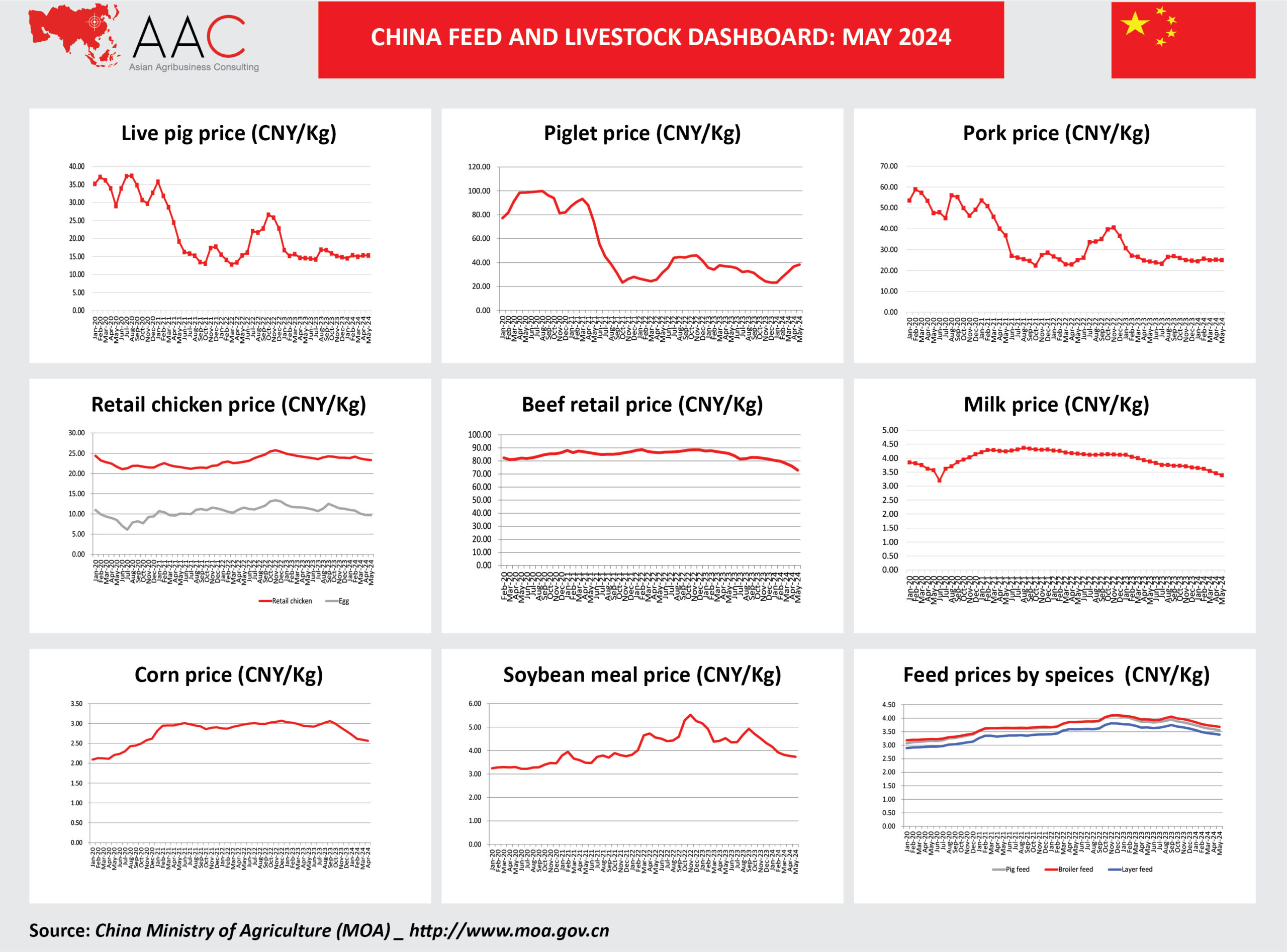

Comments Off on China Feed and Livestock Dashboard: May 2024

China Feed and Livestock Dashboard: May 2024

Comments Off on Industry News: China Livestock, Animal Health & Animal Nutrition

Industry News: China Livestock, Animal Health & Animal Nutrition

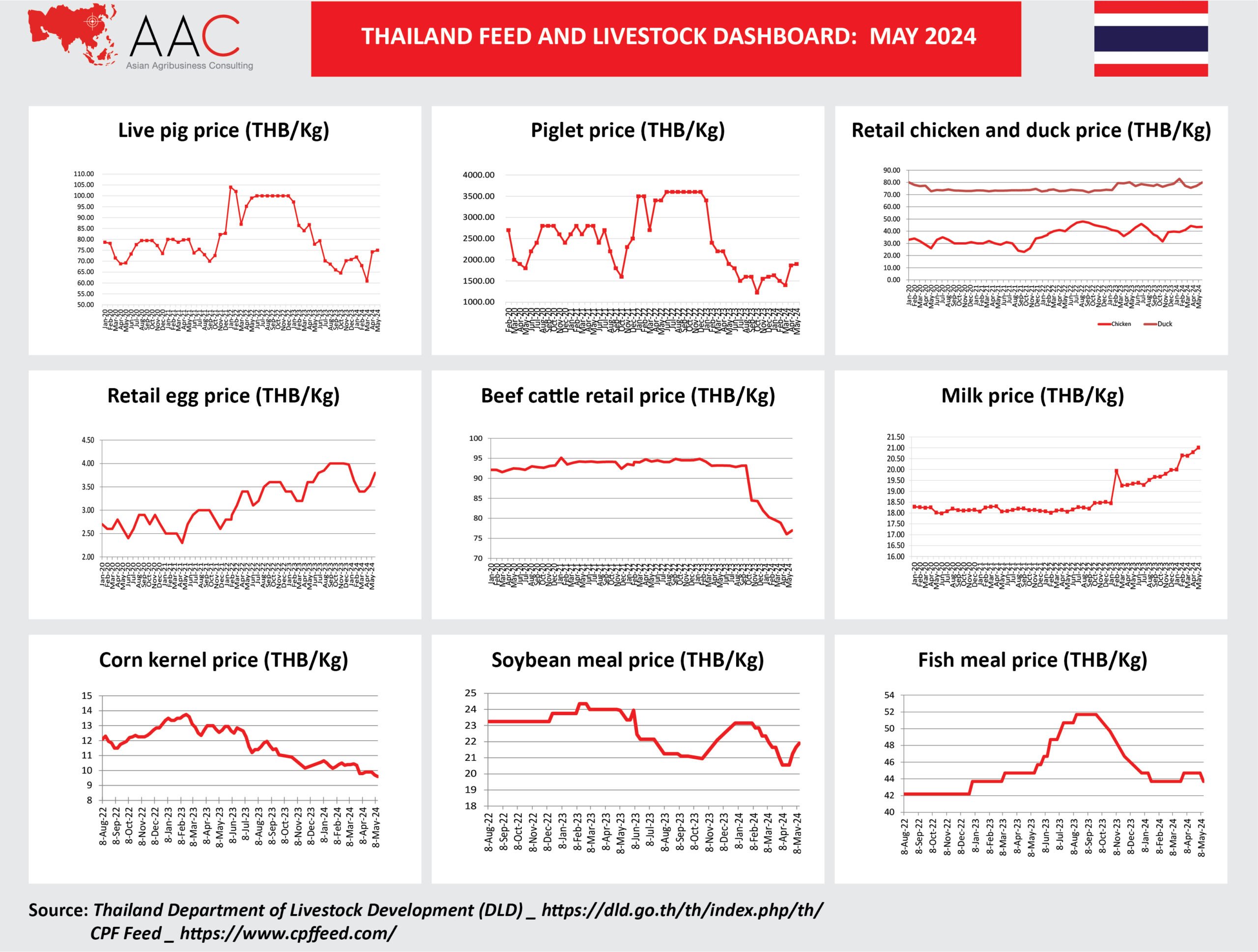

Comments Off on Thailand Feed and Livestock Dashboard: May 2024

Thailand Feed and Livestock Dashboard: May 2024